Exhibition category

Contact address

| Address | 1211 Air Way, Glendale, California, 91201-2497 |

|---|---|

| Telephone | 8182486000 |

| URL | http://www.glenair.com |

| sales@glenair.com |

Main exhibits 1

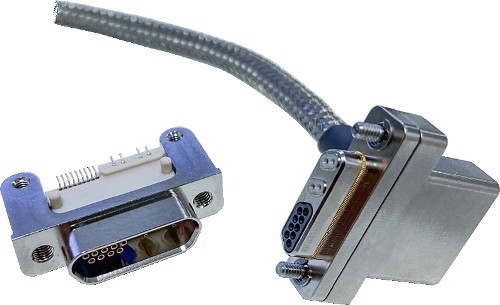

High Speed Connectors - SpeedLine

High-speed connectors and contacts are interconnect devices optimized for compatible performance with popular data transmission protocols, ranging from aerospace-standard data bus protocols such as ARINC 1553 and CAN bus, to networking protocols such 1000BASE-T Ethernet, and peripheral and display protocols including USB 3.0 and SATA. Rugged high-speed connectors of this type incorporate shielded contact technologies suitable for use in aircraft avionics, weapons systems, radars, communication equipment and other aerospace / defense equipment that depend on uncompromised signal integrity.

Ethernet has become the dominant protocol type in high-speed systems due to its ability to efficiently move data over low bandwidth copper cabling. Standard Ethernet can reach up to 100 meters over copper through multiple mated interconnects. The Ethernet protocol is ubiquitous, backward-compatible and subject to ongoing improvement. Other popular protocols include SATA, DVI, HDMI, and SMPTE 3G-SDI which are ideally suited for transmission via shielded (high-frequency) contacts and cables. Each of these protocols poses a unique signal integrity challenge, typically met by a specialized high-speed connector and contact assembly.

high-speed-interconnect-solutions-for-military-defense-aerospace-applications (PDF file - 9,963KB)

Main exhibits 2

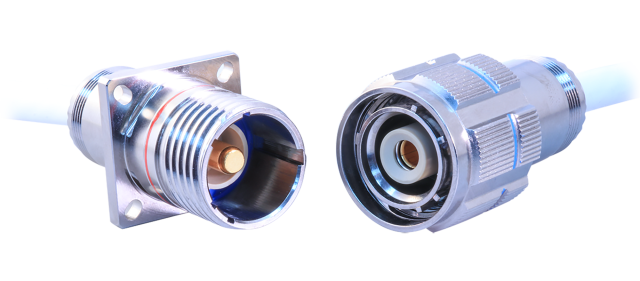

High Power Connector - PowerLoad / PowerPlay

Electrical power generation technology in aircraft has evolved to meet modern requirements for higher power and lighter weight systems. Growing electrical power needs on commercial aircraft—and emerging eVTOL platforms—have caused major changes in

power system architectures to accommodate peakload stress factors in electrical wire interconnect (EWIS) cabling.

- PowerLoad™, the high-vibration, 230°C maximum operating

temperature connectors optimized for applications up to 2000 VAC /1500 Hz, and from 150 – 800 Amps.

- PowerPlay, a high-ampacity multi-pole connector series that combines

the proven performance of MIL-DTL-38999 Series III connector packaging with contact and

dielectric insert technology capable of 2000VAC working voltage.

- Crown Ring crimp, bus bar, and lug style contacts, optimized for high current carrying, high temperature performance.

Power connectors (PDF file - 1,416KB)

Main exhibits 3

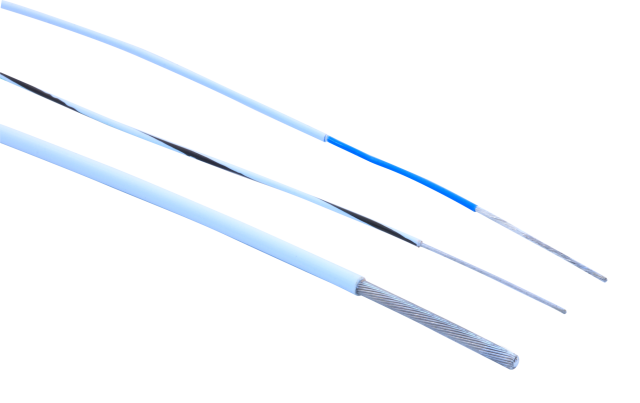

MIL-STAR GS22759 Wire/ GS27500 Cable

Glenair has branded its GS22759 high-temperature aerospace-grade wire, and

GS27500 multi-conductor cables for aerospace applications, under the MIL-STAR brand. These discrete wires and cables are built in accordance with SAE specifications with a “GS” leadoff in place of both the base specification and the part number for individual slash sheets.

MIL-STAR is a high-performance, better-than-QPL discrete wire and cable specification unique to Glenair. The brand covers both protected (insidethe-box) hookup wire, high-durability open-loom wiring, and multiconductor shielded and jacketed M27500-type cable.

M22759 single-ended hook-up wires are the industry standard for insidethe-box mil-aero environments and are optimized for size, weight, high-temperature resistance, and low flame propagation. The hundredplus variants of AS22759 are organized by conductor material and plating, insulation type, wire gage, and single- or dual-wall.