Exhibition category

Contact address

| Address | 1-1-16, Fukumachi, Nishiyodogawa-ku, Osaka-shi, Osaka 555-0034, Japan |

|---|---|

| Telephone | 81727899155 |

| URL | https://www.nttdata-xam.com/en/ |

| info@nttdata-xam.com |

Main exhibits 1

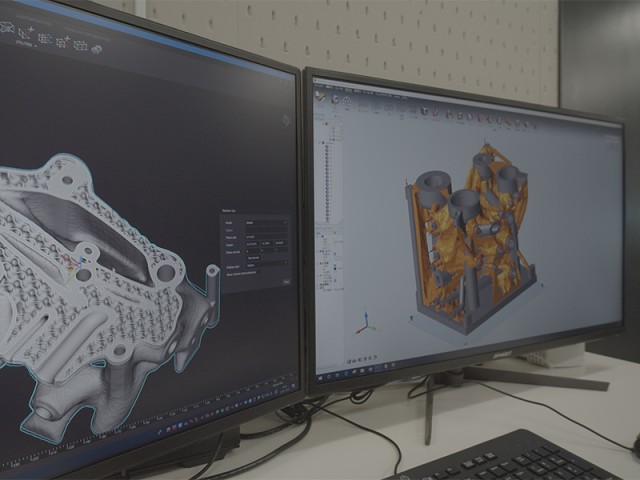

Metal AM Contracted Development & Manufacturing

NTT DATA XAM Technologies, which has been conducting R&D of Metal Additive Manufacturing and contract manufacturing services for more than 30 years,

and Chuo Engineering, which has 70 years of experience in aircraft development and superior technological capabilities in design and analysis,

have been working together as business partners to develop metal AM applications.

We can consult with you on everything from parts screening to quality assurance with our advanced metal 3D printing technology.

What we can offer:

1. Parts Screening

2. Advanced Design and DfAM (Design for Additive Manufacturing)

3. Selecting & Developing material

4. Process Development

5. Prototype & Mass production

6. Post-Process

7. Inspection

8. Quality Assurance

Catalogue (PDF file - 6,755KB)

Main exhibits 2

Past results of our development

Here are some of our achievements.

Past results:

Parts Screening --- Over 500 Parts

DfAM --- Over 300 Parts

Parameter Development --- Over 100 developments

Heat Treatment Conditions Development --- Over 50 developments

Material Development --- Over 35 developments

Devise 3d-printing plans for mass-production---Over 200 Plans / year

Mass-production volume --- Over 2,000 Parts / year

Total 3d-printing time --- Over 300 thousand hours

Inspection data of materials, mechanical property, and dimension--- Over 30 thousand data

We can also develop the parameter with your desired material, please come to our booth and discuss more!

Catalogue (PDF file - 6,755KB)

Main exhibits 3

Examples of metal AM applications we have developed

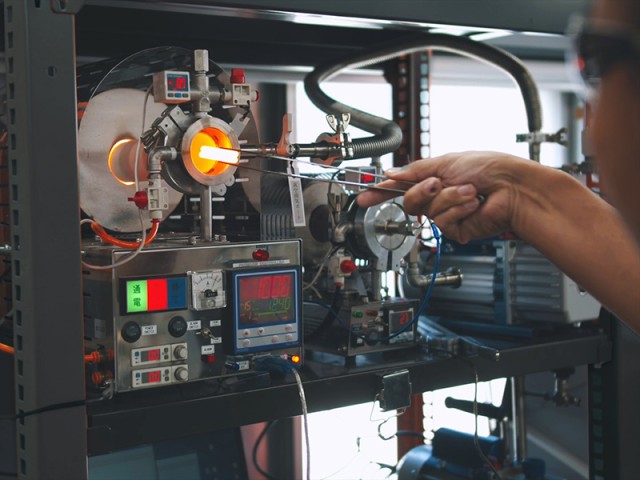

[ Small Combustion chamber ]

Material: CopperAlloy CuCrZr

The material used is a copper alloy, which has high thermal conductivity and is actually used in combustion chambers.

This is a near-practical model with cooling channels and measuring ports.

[ Large combustor with integrated injector ]

Material: NickelAlloy IN718

The injector + combustor are printed on the EOS M 400-4, the largest EOS industrial 3D printer in Japan.

It is a demonstration model to show "large size," "integration," and "improved cooling capacity".

We will also exhibit many other 3D printing parts, so please visit our booth.