Exhibition category

Contact address

| Address | 2-7-17, Shinyokohama, Kouhoku-ku, Yokohama, Kanagawa 222-0033, Japan |

|---|---|

| Telephone | 81452703201 |

| URL | https://www.tpc.toray/en/technology/additive-print/index.html |

| sales.tpc.ug@mail.toray |

Main exhibits 1

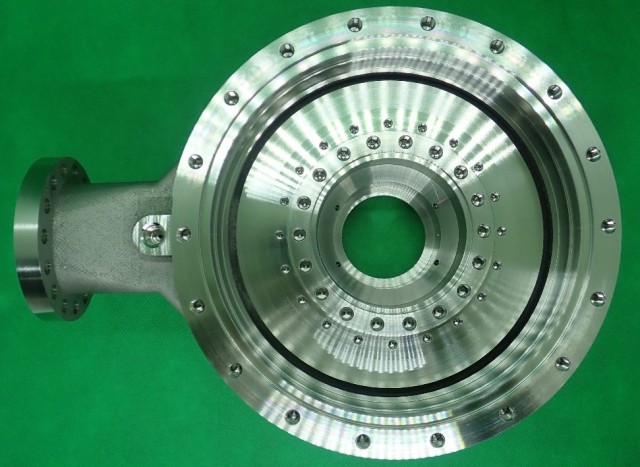

Turbopump casing for liquid rocket engine for JAXA

This casing integrates an inlet manifold for high-temperature gas and a bearing cartridge for cryogenic fluid.

Key Features:

1. Made from heat-resistant material capable of handling high-temperature gas.

2. Complex shape that is difficult to machine.

3. High-precision finishing for fitting with high-speed rotating parts.

4. Equipped with measurement ports to monitor temperature and pressure at various points.

5. Material: Nickel alloy ALLOY IN718.

6. Dimensions: Diameter 185mm, thickness 100mm, length 250mm.

The actual product is on display in our booth!

Main exhibits 2

Metal 3D Printing Services

We specialize in manufacturing high-precision, hard-to-machine products including complex-shaped metal parts made from heat-resistant materials required in aerospace fields.

We support a wide range of materials to meet your specific needs. Our metal 3D printers can create parts using the following metals:

Main Applications:

• Titanium (Ti64): Lightweight and highly biocompatible, used in aircraft and medical fields such as dental implants.

•Inconel 718 : Highly heat resistant, used in aerospace and automotive applications.

• Stainless Steel (SUS316L): High corrosion resistance, used for general machinery parts, as well as parts for food and pharmaceutical manufacturing equipment.

• Pure Tungsten (W): Heat resistant and excellent in shielding, though difficult to machine. Used for parts for medical imaging devices, radiation inspection equipment, and decorative items.

Main exhibits 3

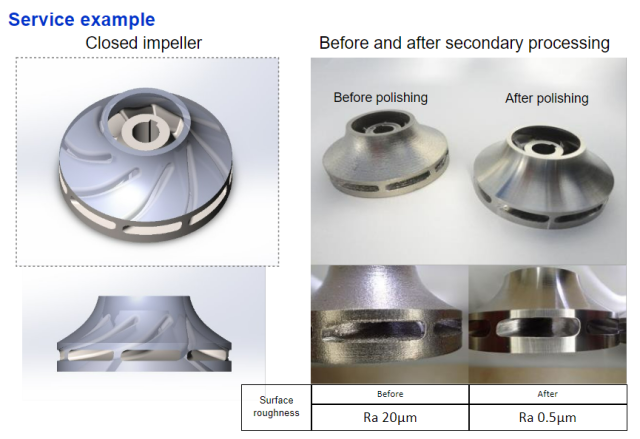

Total Service (Manufacturing + Finishing)

The combination of our metal 3D printing sevices and our precision machining technologies as a secondary process brings a great result to you. Our products are ready-to-use at arrival. You can install it in your devices right away.

We perform a secondary process including polishing of the surface or the interior surface of the products, after metal 3D printing.The secondary process is already taken into consideration in the designing stage, which gurantees our commitment to your needs.

・Complex shapes are achievable

Metal 3D printing is great for making complex shapes which are not achievable by conventional machining techniques. It is widely used for performance improvement or weight reduction of the parts. It can re-produce/make improvements on the parts easily using 3D CAD data.

・Test pieces can be made in a short period of time

Once we have 3D CAD data, we can make the test piece right away. Cost reduction can be expected as molds are not required anymore. Good for your product development phases.

・Small batch manufacturing for various products

Metal 3D printing requires only printing time and material. Making a small batch at once by metal 3D printing can be one of the ways to reduce the cost.

Various shapes with small differences are achievable.