Exhibition category

Contact address

| Address | Bernhaeuserstr. 35 | 73765 Neuhausen a.d.F | Germany |

|---|---|

| Telephone | 004971589489550 |

| URL | https://www.f-zimmermann.com/en/ |

| info@f-zimmermann.com |

Main exhibits 1

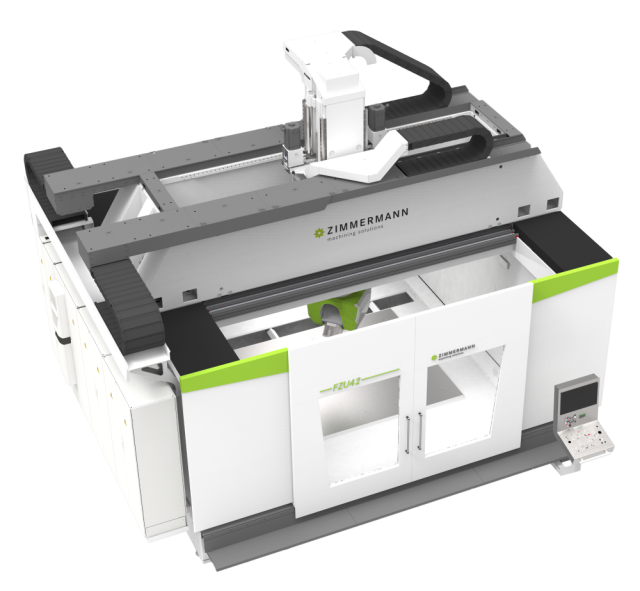

Machining Solutions - Portal Milling Machines

Precision and you. Zimmermann stands for innovative, high-quality and efficient milling solutions - worldwide.

The FZP/FZU line from F. Zimmermann comprises five CNC portal milling machines each, which are characterized by their precision, versatility and performance. There are two variants: P (Performance), in which the machine bed is embedded in the foundation with direct access, and U (Unibody) in which the machine bed is already integrated and therefore no additional foundation is required. The 32 - 42 series are equipped with a thermo-symmetrical portal which ensures greater rigidity and higher thermal stability.

Thermo-symmetrical portal

The special feature is the thermo-symmetrical design with a center-guided Z-slide. This design and the guide arrangement increase stability and also save weight - making the machine more dynamic, more productive and more energy-efficient. To make this possible, Zimmermann has designed its machine portfolio to be thermo(load)-symmetrical.

The centrally guided Z-slider of the gantry in double bridge design has a large cross-section, which makes it extremely stable. Zimmermann achieves a very high level of rigidity with this design. And because no one-sided heating can occur, this increases accuracy enormously. Thanks to the optimized structure, less mass has to be moved and the machine works faster and more dynamically.

EN_ZIMMERMANN_productoverview_0524_web (PDF file - 406KB)

Main exhibits 2

Machining Solutions - Horizontal Machining Center

FZH – highest precision meets automation

Zimmermann’s horizontal machining centers feature pioneering new developments and high-performance milling spindles. They make it possible to manufacture aerospace industry components from a wide range of different materials. The rigid machine bed of the innovative travelling column unit and the highly dynamic Zimmermann milling heads ensure an efficient milling process. The automation system, which is supplied as standard, and the newly developed pallet handling capability are integral components of the horizontal machining centers.

Core technology of the 5-axis Horizontal Machining Center FZH is a water-cooled column system. The innovative traveling column design provides increased stiffness. With increasing depth of immersion into the material, the guide carriage distance increases, thus ensuring more accurate results.

Used in combination with the highly dynamic Zimmermann milling heads, the FZH ensures an extremely efficient milling process during the machining of aluminum and composites.