Exhibition category

Contact address

| Address | 1912-2 Yamakura Agano-shi Niigata 959-1961 Japan |

|---|---|

| Telephone | +81250612400 |

| URL | https://kyoeieng.co.jp/ |

| toiawase@kyoeieng.co.jp |

Main exhibits 1

machining of impellers

《Strong Point》

We can process a wide variety of difficult-to-cut materials and shapes. We can flexibly respond to various requests with short delivery times and high quality. We also produce many prototypes and development products, and can produce even a single item.

《Precision parts processing》

Simultaneous 5-axis machining is possible for machining impellers such as turbine wheels. Our unique machining technology allows for high-precision machining of difficult-to-cut materials and shapes.

《Size》

Tip blade thickness:0.3㎜~

Maximum processing size:φ1250

《Material》

6 - 4Ti, Inconel713C/718/625, Mar-m247,

Titanium, Cobalt chromium, Hastelloy, Tungsten, Carbide etc.

《Riblet processing》

By applying a fine riblet shape to the impeller blades,

air resistance can be reduced and Contributing

to the development of sound suppression effects.

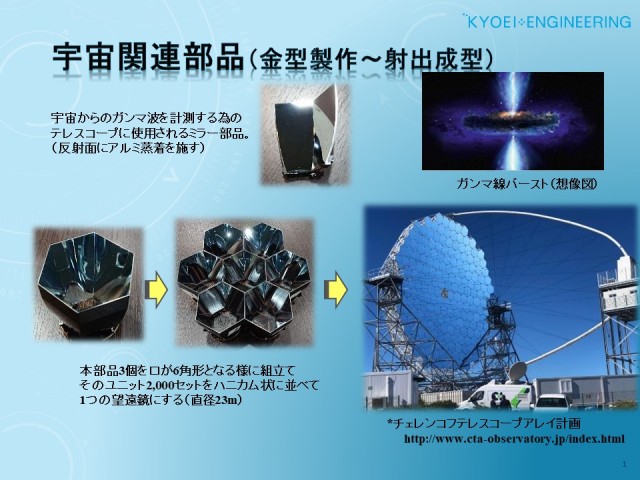

Main exhibits 2

Mirror parts used in telescopes

《Strong Point》

In fields that require high precision, such as automotive, aerospace, medical, and various optical lens parts, we can provide speedy support by completing all processes in-house, from mold design to machining, mold assembly, and molding.

《Maximum size of mold processing》

Maximum 650t molding machine class (mold size 900 x 1300)

《LT/Capacity》

LT 2 weeks (prototype cassette type, depending on shape),

About 5 molds/month

In addition to mass production mold manufacturing, we can also provide short delivery times and low costs with original cassette molds.

《Molding machine size》

Total of 11 units: 35t - 650t

We have experience in mold manufacturing and injection molding in a wide range of fields, including general parts, precision parts, and optical lenses.

《Clean Room》

We have molding machines in our clean room, so molding can be done in a clean environment. We have a proven track record with a wide range of products, from thin-walled parts to thick-walled lenses.

Clean level: ISO8 *Equivalent to US 209E Class 100,000

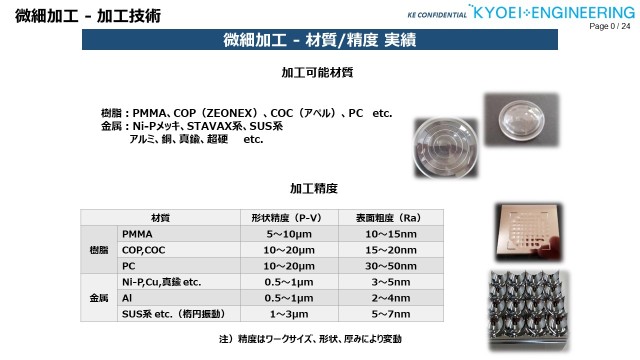

《Micro mirror processing technology》

Not only can we perform mirror finishing on optical lenses and mold inserts with minute shapes, but we can also directly perform mirror finishing on resin materials such as imaging optical lenses and Fresnel lenses that require mirror finishing.

We have many ultra-precision micromachining machines