Exhibition category

Contact address

| Address | ViscoTec Hong Kong Limited, Suite 15, 3/F, Great Eagle Centre, 23 Harbour Road, Wanchai, Hong Kong |

|---|---|

| Telephone | 0085221036515 |

| URL | https://www.viscotec.com/hk/ |

| sales@viscotec-hongkong.com |

Main exhibits 1

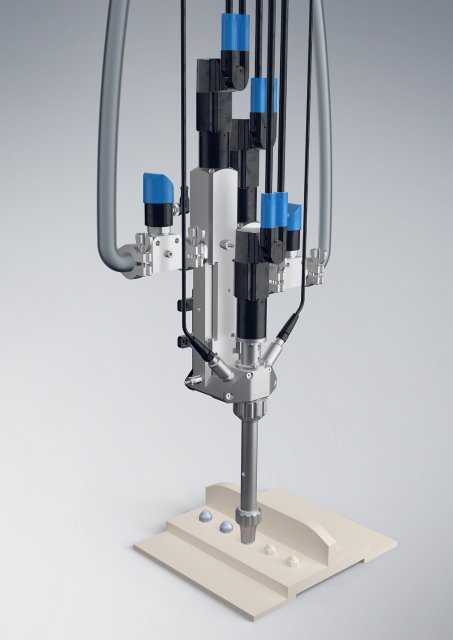

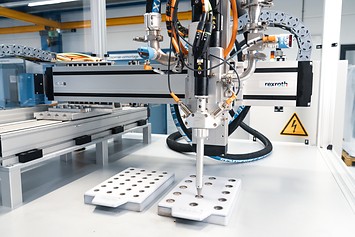

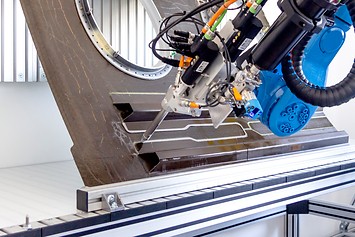

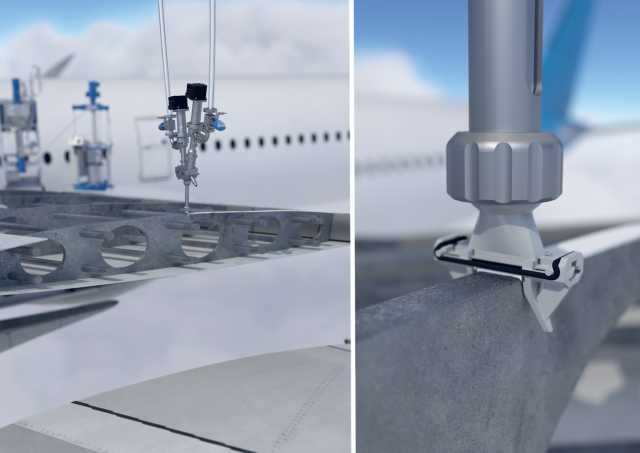

Our dosing systems and components are for conveying, dosing, dispensing, filling as well as for emptying and treating of fluids and pastes. Handling is pulsation-free

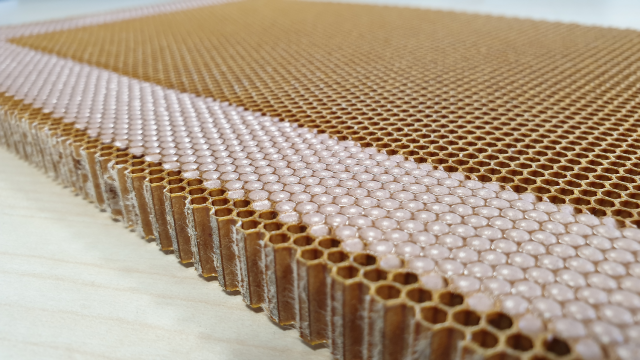

Bonding of structural components and inserts, edge sealing, shimming, honeycomb filling or sealing of rivets and screws in the aerospace industry: ViscoTec dosing systems achieve high-precision dosing results in the aviation and space sector. This makes them the perfect component in your manufacturing process. We are specialists for the automated application of various adhesives, sealants and core fillers for all major OEMs and their suppliers in the aerospace industry and guarantee maximum process reliability. Due to extremely gentle product handling, even shear-sensitive and compressible fluids and pastes can be dosed perfectly.

Dosing applications in the aerospace industry are subject to the strictest secrecy. Therefore, it is not easy to show you concrete examples here. Possible dispensing applications are insert potting, application of 2-component silicones (incl. degassing) or application of 2-component thermal paste for connecting two components and for heat dissipation.

viscotec-broschuere-aerospace-en-web (PDF file - 1,116KB)

Main exhibits 2

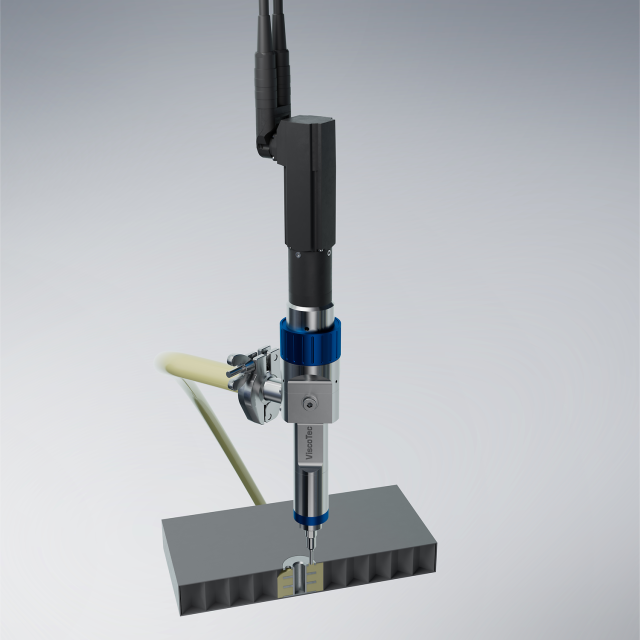

vipro-PUMP and manufacturing samples

▪ Volumetric dosing, regardless of viscosity

▪ For low to high viscosity materials

▪ Particularly suitable for highly abrasive, filled or shear sensitive materials

▪ Modular scalability of volume flow within the model range

▪ Programmable suck-back prevents dripping or stringing of product

▪ Material entry with Tri-Clamp DN 20 connection for optimized material

Data sheet vipro-PUMP M - EN (PDF file - 281KB)

Main exhibits 3

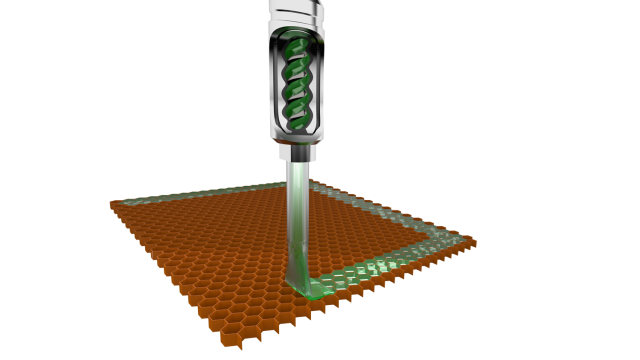

vipro-DUOMIX

Static-dynamic mixing of two materials with same or different viscosities,

extreme mixing ratios, high pressure sensitivity and compressibility.