Exhibition category

Contact address

| Address | 780-1 Kitatoyama,Komaki,Aichi 485-0023,Japan |

|---|---|

| Telephone | 81568486698 |

| URL | https://www.chuo-eng.co.jp/english/ |

| contact@chuo-eng.co.jp |

Main exhibits 1

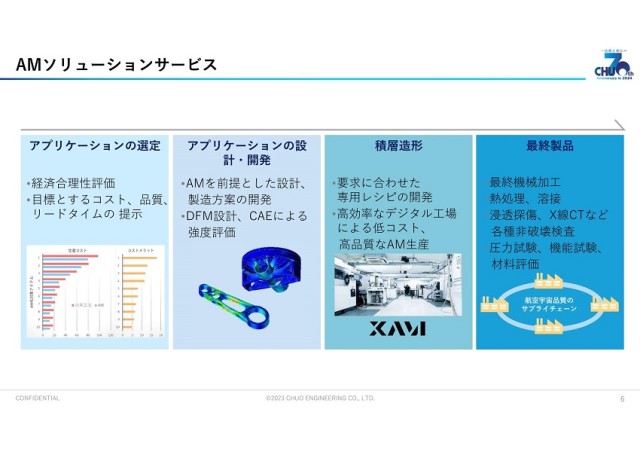

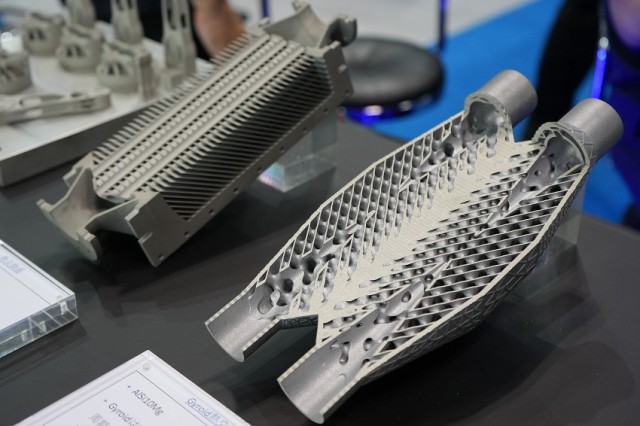

Metal AM Contracted Development & Manufacturing

Chuo Engineering, which has 70 years of experience in aircraft development and superior technological capabilities in design and analysis, and NTT DATA XAM Technologies, which has been conducting R&D of Metal Additive Manufacturing and contract manufacturing services for more than 30 years, have been working together as business partners to develop metal AM applications.

We respond to your request by providing a complete range of the service from design to production enabling cost and weight reduction, and development periods shortening.

Our design and manufacturing methods incorporating Dfam and CAE analysis with appropriate economical rationality assessments help you as a innovative solution.

If you have any problems with AM, please feel free to stop by our booth.

What we can offer:

1. Parts Screening

2. Advanced Design and DfAM (Design for Additive Manufacturing)

3. Selecting & Developing material

4. Process Development

5. Prototype & Mass production

6. Post-Process

7. Inspection

8. Quality Assurance

Company Profile (PDF file - 6,003KB)

Main exhibits 2

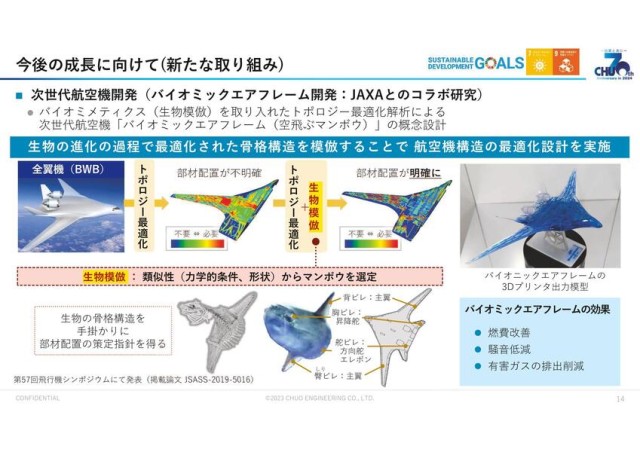

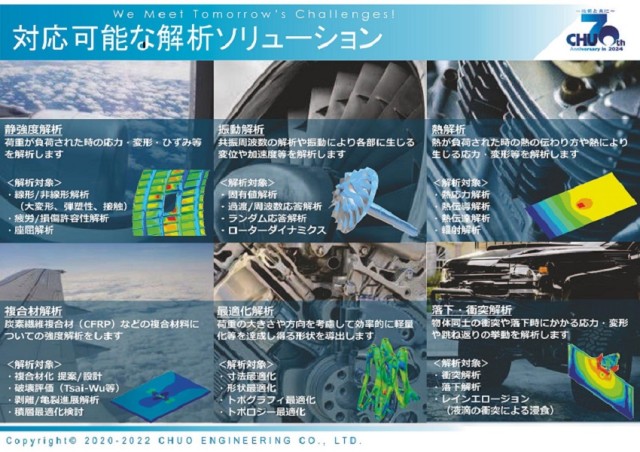

Analyze using advanced technology

Our analysis technology has been improved through our experience under various conditions in the aerospace field.

In some cases, such as in zero gravity or in a vacuum, we have been able to test the suitability of our products under difficult conditions. We have proven our suitability for these conditions with our high-precision analysis technology.

What we can offer:

・FEM analysis

・CFE analysis

・Optimization analysis

・Other CAE analysis

We can provide a high quality of analysis using proprietary technology.

please come to our booth and discuss more!

Analysis Technology List (PDF file - 1,039KB)

Main exhibits 3

Introduction of "Manufacturing" One-Stop Solution Service

We provide a one-stop service for many manufacturing processes from design to manufacturing and testing.

[Reliable design capabilities]

・Our specialists from wide range of engineering fields including mechanical, electrical, and electronic software handle the job unitedly from specification formulation stage.

・We propose unprecedented weight reduction, mechanisms, and shapes

by using design methods that incorporates CAE analysis and utilizing 3D metal modeling

[We respond you with many reliable partner manufacturers]

・Easily handle rush orders at our own factory

・Incruding NTT DATA Zam Technologies, we work together with many partner companies to respond to your requests such as specific delivery dates and unique requirements varied from ultra-precision compact products to large canning products

【Specialties】

・ We develop prototyping products with strict requirements (temperature, pressure, strength, accuracy, etc.) from 1 item.