Exhibition category

Contact address

| Address | 209 Kinzokudanchi Kakamigahara City,Gifu,504-0957 JAPAN |

|---|---|

| Telephone | +81583800003 |

| URL | http://tokuda.co.jp/ |

| sawai@tokuda.co.jp |

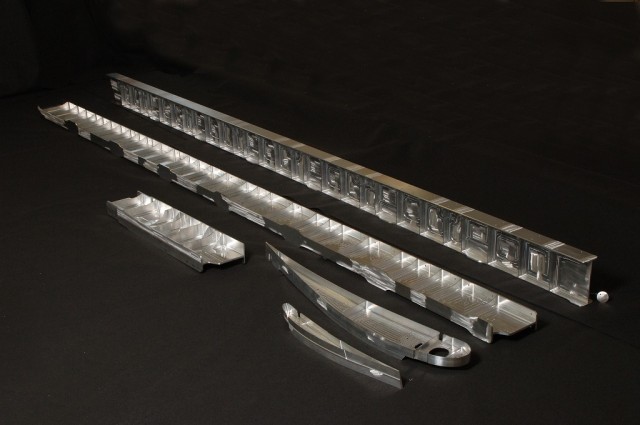

Main exhibits 1

Machined parts for aircraft

- We have developed our own stocker that can store six 236 x 78.7 inch pallets. By supplying pallets with pre-set products to the processing machine, we have achieved long periods of continuous operation.

- We have 14 pieces of equipment equipped with pallet changers that allow for continuous operation.

- Long plate materials are used, and one-chuck processing can be performed in sequence for continuous operation. Material yield is improved by more than 30% compared to normal one-chuck processing.

- We use one-chuck processing of titanium parts using a LANG.

設備一覧 英訳 (PDF file - 391KB)

Main exhibits 2

Wind tunnel testing and various display model manufacturing

- We can manufacture a variety of sizes, from full-size to scaled-down.

- We can manufacture from the data you provide using a variety of materials and methods, such as cutting, 3D printing, and FRP modeling.

- We can also manufacture models by scanning the actual item or a scale model.

- We can provide consistent service from design and manufacturing to on-site installation.

A4パンフレット英訳 (PDF file - 240KB)

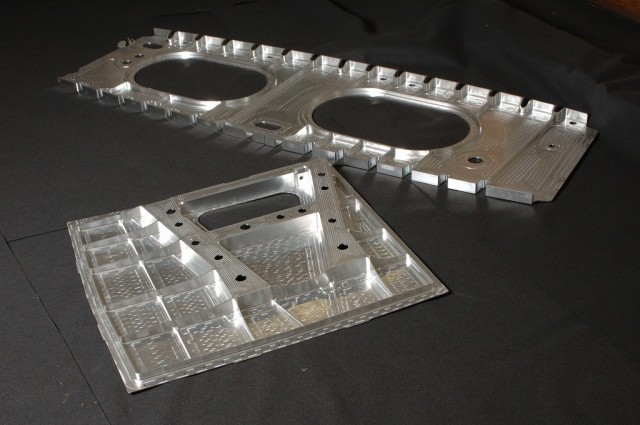

Main exhibits 3

Design and manufacture of aircraft jigs and tools

・We design and manufacture various jigs and tools used in the manufacturing of aircraft parts.

・We manufacture a variety of jigs and tools, including molding jigs and processing jigs.

・We can handle a variety of materials, from iron-based metals and aluminum-based metals to epoxy-based resins, depending on your request.