Exhibition category

Contact address

| Address | 2-33 Technoplaza Kakamigahara city Gifu prefecture Japan |

|---|---|

| Telephone | +81583223135 |

| URL | https://www.wako-gifu.co.jp/ |

| n-chatani@wako-gifu.co.jp |

Main exhibits 1

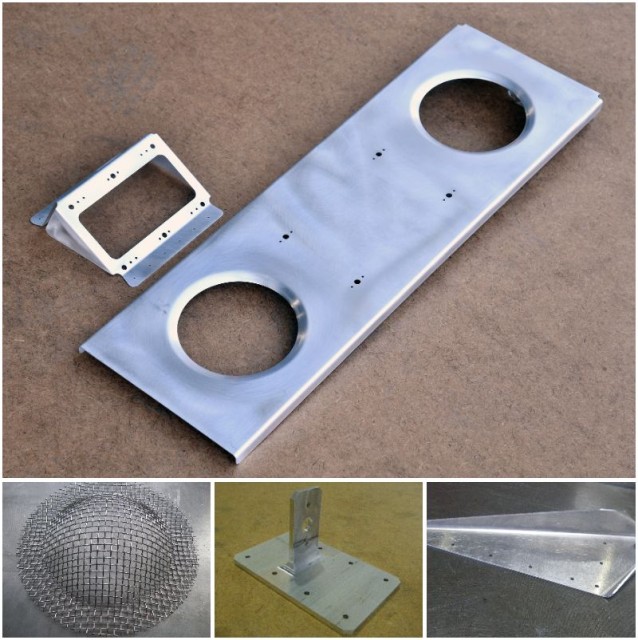

Aircraft Jigs and Tools

Our company possesses deep expertise and many years of experience in welding technology, handling a wide range of materials including iron, aluminum, and stainless steel. Especially in the manufacturing and repair of work scaffolds and transportation dollies, we utilize our unique techniques to improve work environments, enhance work efficiency, and strengthen safety.

We also provide rapid delivery capabilities and customization services, allowing us to flexibly respond to urgent customer demands. This enables us to quickly deliver products optimized for specific requirements and work environments, thereby pursuing increased customer satisfaction.

Our products are diverse and have garnered satisfaction from many customers. By providing high-quality products and services that meet customer needs, we have built trust and a solid track record. Moving forward, we will continue to strive for the provision of better products and services through technological innovation and service improvement.

Main exhibits 2

Aircraft Sheet Metal Parts

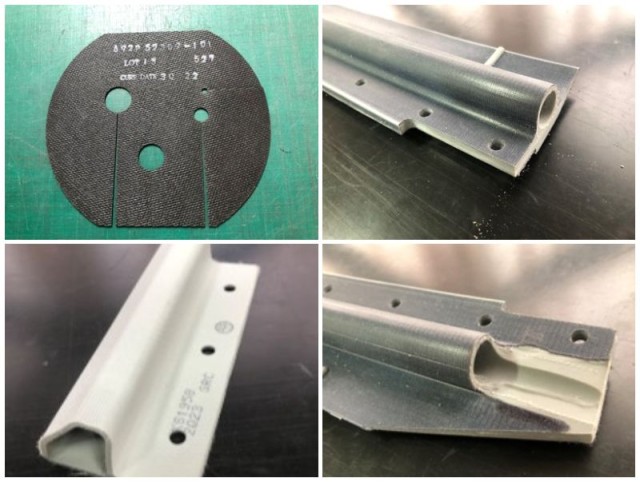

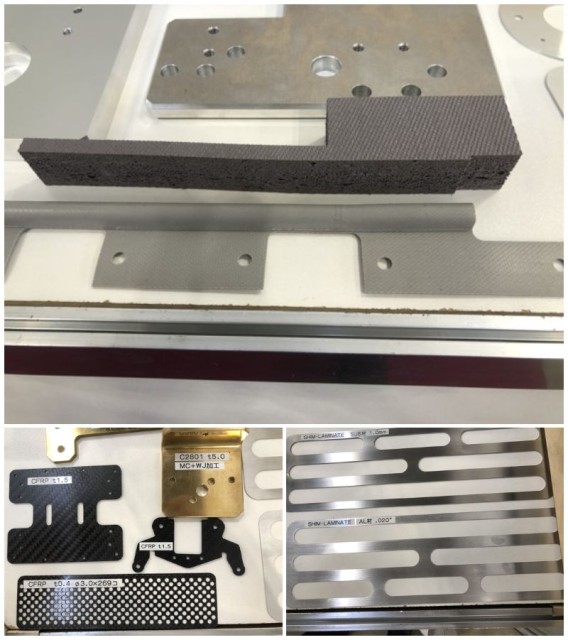

Our company specializes in manufacturing a wide range of parts for various models, handling both small and large production quantities. In particular, we excel in the processing of rubber products using custom-made molds that we develop in-house. These specialized molds allow us to deliver products that meet detailed specifications—such as overall length, shape, hole diameter, and hole pitch—while maintaining the flexibility inherent to rubber materials. This capability enables us to provide products with short lead times.

Additionally, we are proficient in product processing using water jet technology. Water jet cutting employs high-pressure water to slice through materials, making it highly effective for machining difficult-to-cut materials with precision. This method is especially advantageous in aerospace component manufacturing, where it is crucial to avoid thermal effects. With water jet cutting, we can process parts without causing alterations or distortions due to heat. This technology allows us to produce complex shapes and high-precision parts quickly and with exceptional quality.

Utilizing these technologies, our company is committed to meeting the diverse needs of our customers by delivering high-quality products with short lead times. We continuously strive to improve our techniques and ensure the highest quality standards in all our offerings.

Main exhibits 3

Others

In our assembly operations, as part of our improvement activities, we use production management boards. These boards compile technical materials such as processing procedures and key points during processing. By utilizing these boards, we can prevent variations in quality and procedures among workers, thereby ensuring efficient progress in our operations. This initiative has significantly reduced defects.

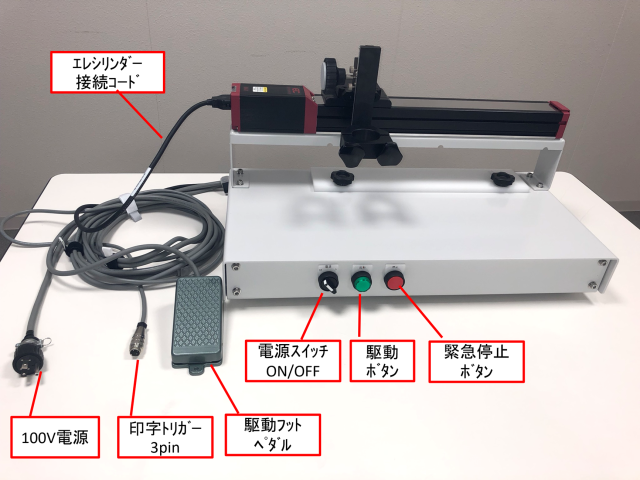

Additionally, for product identification, we use an in-house developed inkjet printer. This printer, with both its operational components and software developed internally, reads product information via barcode to achieve accurate and error-free identification. This system has been well-received by many customers who require precise identification.

Furthermore, our company develops and sells aluminum frame aircraft. We handle all processes in-house, from design and manufacturing to sales, delivering high-quality products. This ensures our customers, who demand reliable products, are highly satisfied.