Exhibition category

Contact address

| Address | 159-1 Mukogayumi, Iinan-cho, Matsusaka City, Mie Prefecture |

|---|---|

| Telephone | 0598322200 |

| URL | https://www.mitsuchi.co.jp/ |

Main exhibits 1

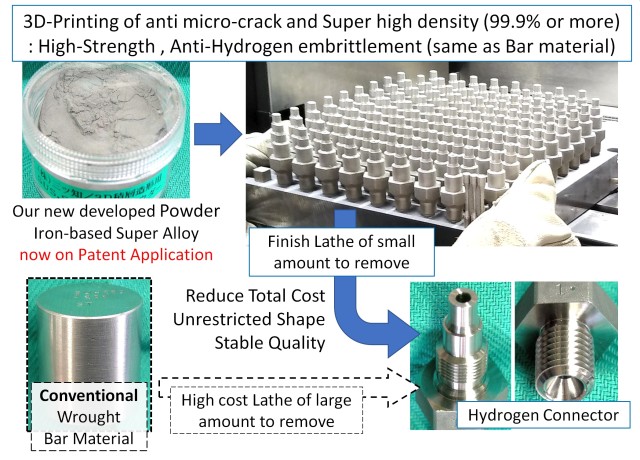

Hydrogen Connector of High-strength & Productivity - with New developed Iron-based Super-Alloy & 3D Printing -

MITSUCHI developed a Net-shaping method with 3D Printing and Iron-based Super-Alloy of SUH660 (A286) Modified, which has suitable property as High-Strength Joint used for High-Pressure or Liquefied Hydrogen Piping. This Development achieved to improve Total Productivity and Fewer Designing Constraints.

[ Detail ]

With mean compositions of SUH660 (A286) powder and the conventional 3D printing, Micro-Cracks occur in the 3D-printed product.

MITSUCHI identified the chemical compositions that suppress cracks, and, found the optimal laser Irradiation Conditions.

Mechanical Properties of the developed product achieved to be equivalent to that of Conventional Machined Products of Wrought Bar material.

Hydrogen Connector_Mitsuchi Leaflet_240313 (PDF file - 846KB)

Main exhibits 2

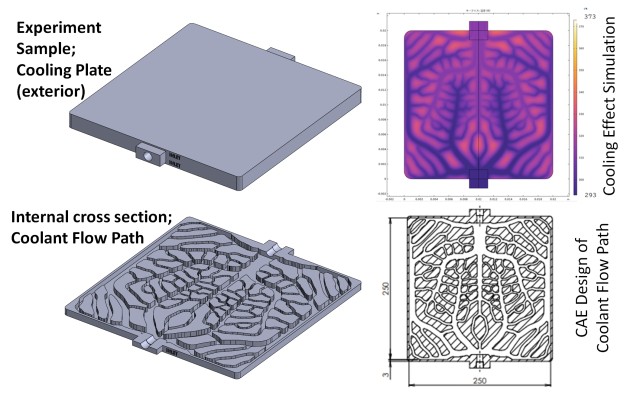

Mold Cooling Insert with High Cooling Efficiency - Unique Internal Flow Path of 3D Printing with Durable material -

MITSUCHI developed Unique Mold Inserts with High Cooling Efficiency. This was achieved using CAE and 3D printing combined with Effect Simulation and Coolant Flow Path Design.

Furthermore, we offer a New Powder Material specifically for 3D printing with the corrosion resistance and high strength suitable for mold cooling fixtures. ( Now on Patent application )

[ Detail ]

Injection Molds for Resin Products require strict temperature control to ensure the product Quality and Productivity. So our challenge was to create a Highly Efficient Cooling System for severe thermal cycles of the molds. Traditionally, Mold Inserts have been made with drilling holes in the steel to provide Coolant Flow Path. Such Flow Path was linear and had many restrictions to design, so it was not possible to obtain a sufficient cooling effect.

Mold Cooling Insert_Mitsuchi Leaflet_240313 (PDF file - 725KB)

Main exhibits 3

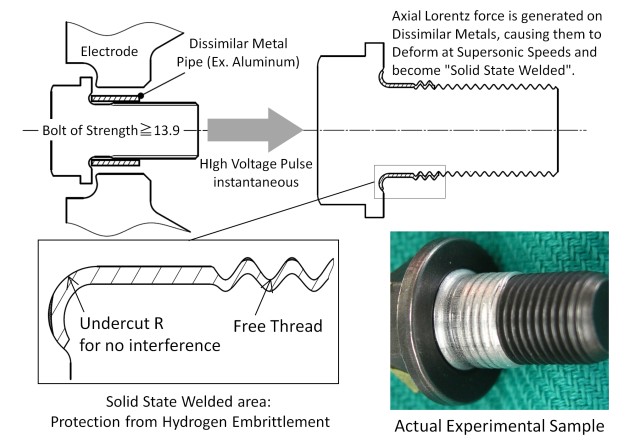

High Strength Bolt with Resistance to Hydrogen Embrittlement - Electromagnetic Pulse Welding method -

Mitsuchi developed "High Strength Bolt with Resistance to Hydrogen Embrittlement" using Electromagnetic Pulse Welding method.

There is no need to change the dimensions or layout of the fastening structure, and no need to change the base metal or strength. The Torque Coefficient is never changed.

[ Detail ]

Hydrogen Embrittlement occurs at the area of either "Under Head corner R" or "Thread Root" free from engagement.

Developed product coats such Harzard Area with Dissimilar Metal of Superior to Ionize than the bolt material. The Anodic Reaction occurs on the surface of this coating, which Disperses Hydrogen Penetration Away from Harzard Area.

(Patent No. 7064529)