Exhibition category

Contact address

| Address | 13414-1 Minamiharayama, Ochiai, Fujimi-machi, Suwa-gun, Nagano 399-0214, Japan |

|---|---|

| Telephone | 0266625283 |

| URL | https://goko-denko.co.jp |

| y.takahashi@goko-denko.co.jp |

Main exhibits 1

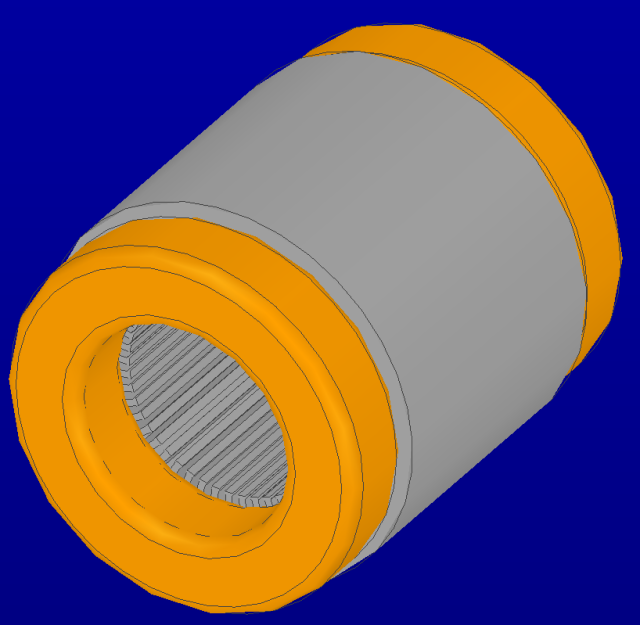

Axial gap motor with Litz wire

Aviation industry is also seeking electrification to decarbonize

Mass-to-output ratio and space efficiency are important for flying!

We propose an axial-gap motor that can be installed in a small space.

This motor uses a square Litz wire for the winding to reduce AC copper loss.

Two square Litz wires are used in parallel to minimize the winding space at the coil end. The core material is made of pressed iron.

The back of the coil is an aluminum frame, which is lightweight and has low heat dissipation resistance, and the rotor contributes to cooling by pushing hot air out of the center of the rotor by centrifugal force due to rotation.

Of course, it can also be used as a generator.

Main exhibits 2

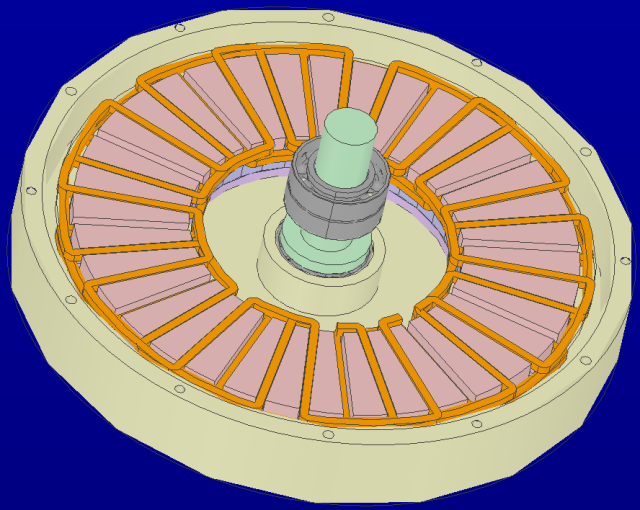

State-of-the-art motor technology for high occupancy and reduced eddy current losses

In order to meet the diverse needs of our customers, we focus on the design, development, and manufacture of motors with high occupancy ratios.

Compared to conventional designs, motors with a high occupancy ratio can carry more current in the same size, resulting in higher output and improved efficiency.

In order to achieve high occupancy, we use our proprietary technology to form the optimum magnetic circuit to provide motors with superior performance.

Furthermore, our motors are designed specifically to reduce eddy currents.

Since eddy currents cause motors to lose efficiency and generate heat, it is extremely important to minimize them.

We use our proprietary winding technology to suppress the generation of eddy currents, thereby increasing the efficiency of our motors.

We can also customize our products to meet your specific requirements, so please check our technical capabilities.