Exhibition category

Contact address

| Address | U Panasonicu 376, Pardubice, 530 06, CZECH REPUBLIC |

|---|---|

| Telephone | 00420605407306 |

| URL | https://www.toseda.cz |

| jiri.zelenka@toseda.cz |

Main exhibits 1

Extended Pot Life Resins for Out of Autoclave Processing

TOSEDA has developed a binder for a production of composite fuel tanks out-off autoclave processing.

The system has exceptional properties as low viscosity, long pot life, good mechanical properties, low curing temperature and others. The low viscosity and long pot life are particularly important to produce large containers. A tank was prepared from this binder and carbon fibre by winding and subsequent infusion. The tank was successfully tested. The resin system complied the requirements for outgassing. The curing temperature is 130°C and curing time 13 h. The system has a high resistance against crack propagation. The cured composite system was determined the Interlaminar fracture toughness mode IC (450) and the Interlaminar fracture toughness mode IIC (2100).

See below for binder and composite properties.

Parameter-binder for composites tanks (PDF file - 132KB)

Main exhibits 2

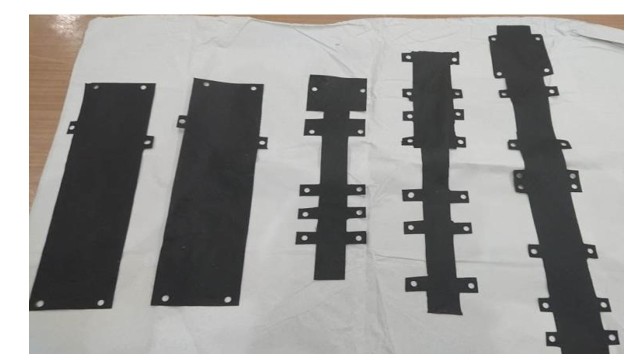

Thermal Interface Materials developed by TOSEDA for space Industry - TIM

Thermal Interface Materials developed by TOSEDA for space Industry.

Thermal interface materials (TIM) help to dissipate the parasitic heat generated by the electronic units. Parasitic heat can cause electronic units to overheat. However, heat dissipation is limited by uneven surfaces. TIM systems are necessary to increase the efficiency of parasitic heat removal. TOSEDA has developed an electrically non-conductive Pad (4SPACE toseda 169-2) and Paste (4SPACE toseda 149-3) for the space industry. Both systems were certified for space using. Both TIM systems have high resistance to temperature cycling and exposure to electrons. There is no phase separation even after long-term temperature cycling observed in other competing commercial systems. A great advantage of the developed systems is also their thermomechanical properties.