Exhibition category

Contact address

| Address | 1-13-12, Amida,Takasago,Hyogo 676-0815 Japan |

|---|---|

| Telephone | 08085122050 |

| URL | https://5jiku.net/ |

| e_taneichi@dainichiss.co.jp |

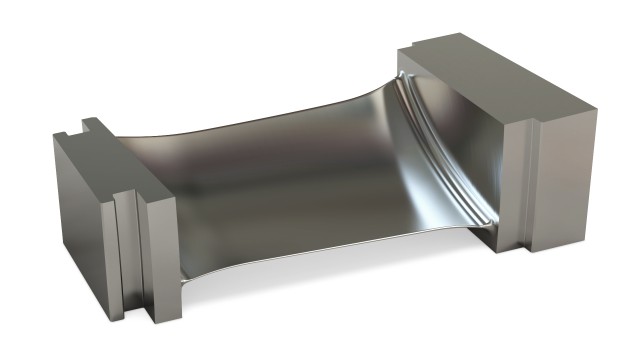

Main exhibits 1

Machined Thin-Walled Elbow

With our high-quality 5-axis machining technology, we can handle the production of precise and complex shapes, achieve thin-walled and lightweight designs, and work with difficult-to-machine materials.

By utilizing our multi-process machining technology, we streamline operations, enabling quick ramp-up from prototyping to mass production in a short period.

We also provide welding, surface treatment, heat treatment, and NDI for part manufacturing, as well as equipment assembly.

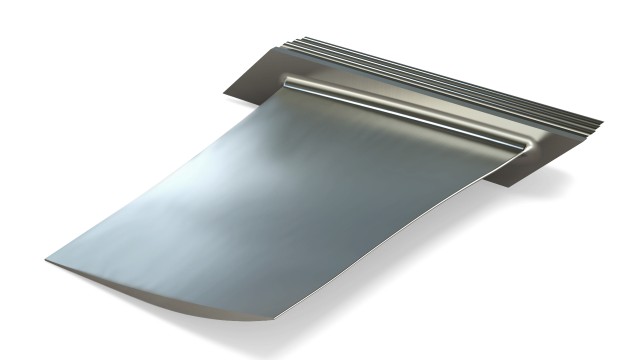

Main exhibits 2

Machining of blades (both stator and rotor) made from difficult-to-machine materials

Engine Performance Enhancement: Increase the air pressure entering the combustion chamber.

Heat Resistance: Deliver high-temperature, high-pressure gases to the turbine blades.

Materials: Difficult-to-machine materials such as Inconel, Waspaloy, and Ti-6Al-4V.

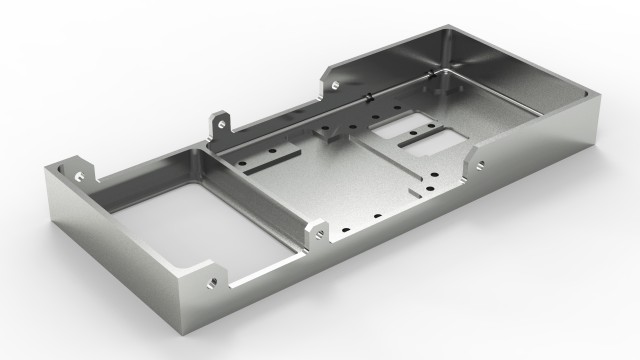

Main exhibits 3

thin-walled case

Aluminum Alloys

A2017, A5052, A6061

Material Dimensions

φ50x15, 50x50x15, 150x200x15, etc.

Machining Method

5-axis machining

Features

With 29 units of 5-axis machining centers, we can handle mass production of complex parts requiring 5-axis machining. For parts roughly the size of a palm, depending on the machining time per piece, we can consider monthly production of up to 1,000 units. Of course, we also support prototyping, enabling us to handle everything from the initial ramp-up to mass production seamlessly.

We are particularly adept at handling thin-walled machining for weight reduction and intricate machining required for parts that interact with internal components.