Exhibition category

Contact address

| Address | 2-2-1 LMT4410 Minatomirai, Nishi-ku, Yokohama City |

|---|---|

| Telephone | 0454143390 |

| URL | https://www.grobgroup.com/en/ |

| info@jp.grobgroup.com |

Main exhibits 1

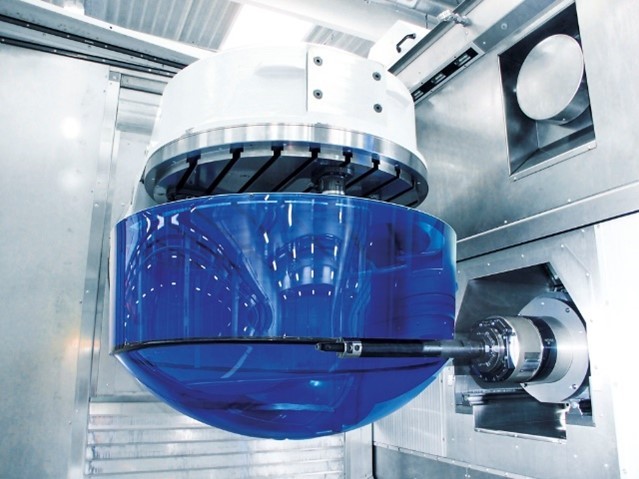

G Series Machining Center

GROB's G series, simultaneous horizontal 5-axis machining center has a unique axis configuration and spindle "Tunnel Concept" that provides high rigidity and prevents tool interference in the work area during tool change. This allows a wide range of workpiece to be machined with a single machine concept, From aerospace aluminum frame parts to titanium blisks. The G series also offers the option of a simultaneous 5-axis mill-turn machining center for turning operations, enabling a wide variety of machining operations to be performed by a single machine.

With the tunnel concept, the G series machining center has an extremely long travel distance in the Z-axis, which allows the use of long tools and providing close accessibility to workpiece. This allows the use of a wide variety of tools, from short tools of 100 mm to long tools of over 500 mm, without caring about interference with the workpiece. Furthermore, the A-axis has a wide rotation range of 230° (-185° to +45°), making an easy and efficient chip removal by overhead machining with the inverted table.

The machine lineup includes G150 with a table diameter of ⌀ 380 mm, G350 with a table diameter of ⌀ 570 mm, G550 with a table diameter of ⌀ 770 mm, and G750 with a table diameter of ⌀ 950 mm. Options include the HSK-A80 spindle (only for G350), and a table with a centering table or a tandem drive table with a clamping arm can also be selected for mass production machining of engine blades.

Main exhibits 2

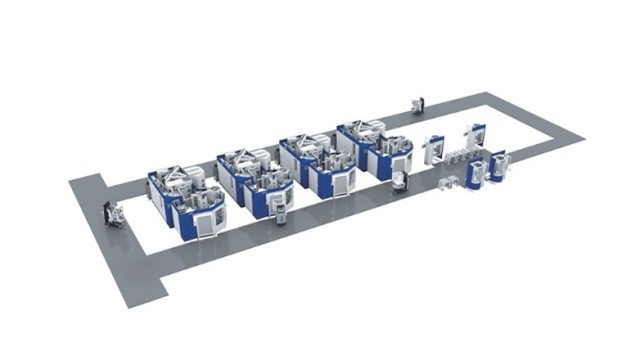

GROB Automation Solutions

GROB offers not only pallet changers, but also a wide variety of automation solutions such as mass-production machining cells using robots and combinations of AMR (Autonomous Mobile Robot) and machining centers. Recently, labor shortages have become a major theme in the manufacturing industry, and GROB supports the optimization of customers' production lines by proposing automation solutions tailored to customers' machining needs and automation requirements.

The mass-production robot cell can handle both workpieces and pallets, enabling both mass production by direct robot loading of blocks and round bars and single-part production at a manual setup station. This enables medium-mixed, medium-volume production or mixed production of both high-volume and low-volume products.

GROB's automation solution with AMR enables highly sophisticated and complex automation, not only by transferring pallets to multiple machines, but also by transferring tools, connecting to other equipment such as inspection machines, and flexible for future expansion, such as installing additional machines. Unlike conventional AGVs installed with magnetic tape, the AMR unit is highly flexible and easy to install. The system requires almost no dedicated programming or teaching and can share data among multiple AMR units to update factory maps and optimize routes at all times.

Main exhibits 3

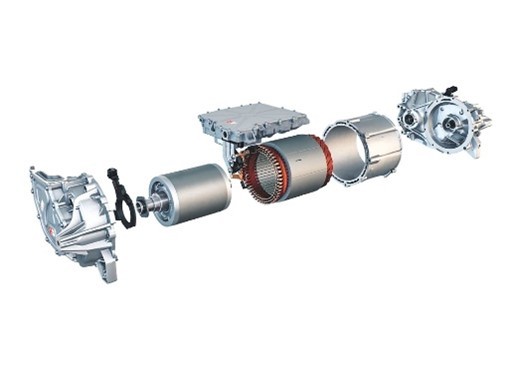

Electric motor winding and assembly machines

In recent years, we have been hearing more and more about electrification of aircraft, eVTOL, and electric aircraft in the aerospace field. GROB also provides electric motor assembly equipment for aircraft based on our experience and achievements in the automotive industry. GROB can provide multiple electrification solutions such as stator assembly, rotor assembly, motor unit assembly, and gearbox unit machining.

For winding machines, GROB uses CNC and robot grippers to bend copper wire, which provides more flexibility than die bending and allows multiple types of copper wire pins to be manufactured on a single machine. The same machine concept can be used for everything from small quantities for near prototype production to large-scale production.

In addition to providing equipment for manufacturing, we also offer trial production, product development cooperation, and simultaneous engineering (SE) to support our customers from the initial stages of their electrification projects. Please take advantage of GROB's many years of experience and extensive network in the new field of electrification.