Exhibition category

Contact address

| Address | 2048-1, Kamitome, Miyoshi-machi, Iruma-gun, Saitama, 354-0045 Japan |

|---|---|

| Telephone | 81492743030 |

| URL | https://uchida-japan.com/ |

| uchida_info@uchida-k.co.jp |

Main exhibits 1

3D PRINTED MOLD

We are currently working on the recycling of CFRP molded products and molds.

This year, we succeeded in producing high-precision molds as CFRP molds for AutoGrave by using a 3D printer to produce molds from pelletized recycled materials supplied by a major manufacturer for testing purposes.

After delivering CFRP products manufactured with CFRP molds made of such recycled materials to customers, we store the molds in-house for a period of time and then reuse the molds as recycled materials.

Demand for recycled CFRP molds is expected to increase as aerospace-related products, which are expected to grow significantly in the future, often use CFRP components.

By thoroughly recycling CFRP, which is said to be difficult to recycle, we aim to minimize the disposal of resources and realize a circular economy.

Main exhibits 2

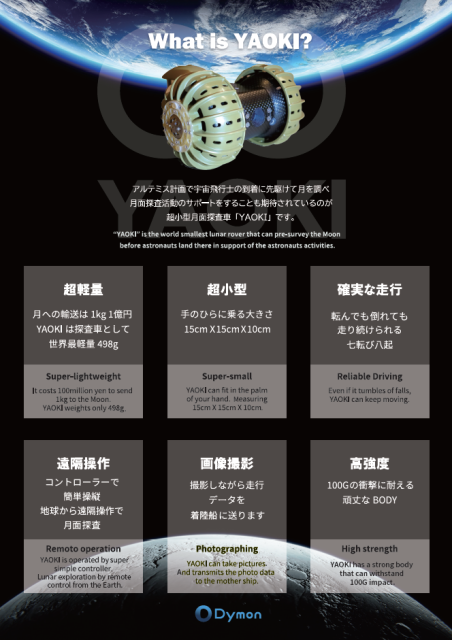

YAOKI

Dymon, a Japanese robotics and space development company, has signed a payload contract with Astrobotic, the company selected by NASA to carry out the lunar transportation contract for the Artemis project, which aims to land a man on the Moon in 2025. YAOKI".

We have supplied parts for the YAOKI chassis, which is small enough to fit in the palm of your hand (15 x 15 x 10 cm) and has an ultra-light design of 498 g, yet can withstand a 100 G shock.

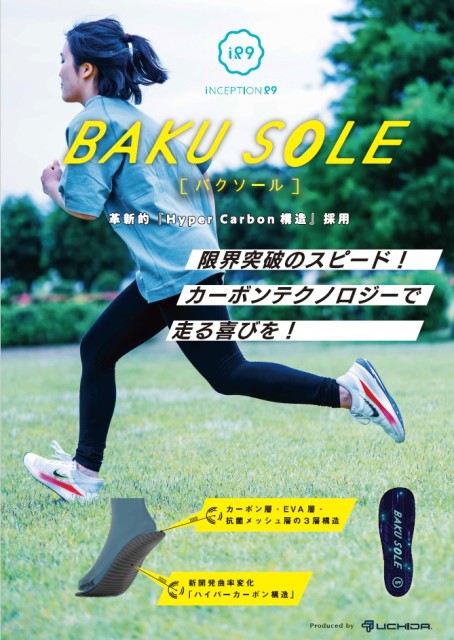

Main exhibits 3

CARBONNE MIRAI /CARBON INSOLE BAKUSOLE /LOW-COST CARBON ANKLE FOOT ORTHOTIC DEVELOPMENT

The tip of the carbon fiber hair of the "Carbonne MIRAI" is a masterpiece of our craftsmanship that you should definitely see.

And the carbon insole "Bakusole".

BAKUSOLE and LOW-COST CARBON ANKLE FOOT ORTHOTIC DEVELOPMENT are derivative models using the technology of C-FREX, which won the JEC Innovation Award in 2016 and completed its development as UCHIDA's last prototype that satisfied all the required functions. We started this project with the thought, "Can we contribute to the company and make children smile with the technologies we have cultivated through prototype development? We hope to expand these technologies into the development of products that are "useful in people's daily lives.