出展カテゴリー

連絡先

| 住所 | 1011 Polytek St |

|---|---|

| 電話番号 | 6137443530 |

| URL | https://www.gastops.com/ |

| sales@gastops.com |

主な出展物1

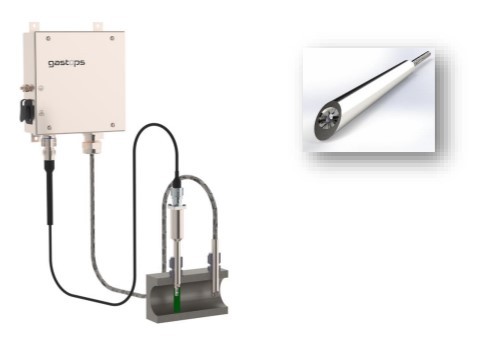

MetalSCAN

Rolling Element Bearings and Gears are critical components of power and propulsion systems.

Damage to these components is one of the leading causes of unplanned engine and gearbox removals. MetalSCAN is the worlds leading technology for online monitoring and quantification of wear debris. Key characteristics of MetalSCAN include:

• Early, reliable failure detection

• Flow-through design

• Particle size & type information (Fe/NFe)

• Particle mass information

• Enables condition-based maintenance with diagnostics

and prognostics capabilities

主な出展物2

ChipCHECK

When wear debris is detected in an engine or gearbox, maintainers need accurate information about its source. Traditional methods of wear debris analysis are often subjective and require samples to be sent offsite, which can take days to complete. ChipCHECK is a rugged field deployable material analyzer that enables at-platform maintenance decision-making. Key

characteristics of ChipCHECK include:

• Analysis of particles > 80 µm

• Less than two hours training required

• Conformance to ASTM D8182

• Particle size information

• Alloy type information

• Go/No-Go Support

主な出展物3

Oil Condition and Contaminations Monitoring

Lubricants serve as the vital lifeblood for engines and gearboxes. However, their degradation and contamination rank among the primary factors contributing to wear debris and overall

deterioration. Gastops is introducing a groundbreaking solution integrating lab grade

precision into a fully online, real-time system. Key characteristics of the Oil Condition &

Contamination monitoring system include:

• Additive depletion

• Fuel dilution quantification

• Water contamination quantification

• Metallic particle counting and sizing

• Suitability for reciprocating engine, gas turbine

and gearbox lubricants

• Enabler for condition-based maintenance with

diagnostics and prognostics capabilities