Exhibition category

Contact address

| Address | 1346 South Legend Hills Drive, Clearfield UT 84015 |

|---|---|

| Telephone | 8015890092 |

| jp.rouliez@es3inc.com |

Main exhibits 1

Engineering Services for Aerospace Industry

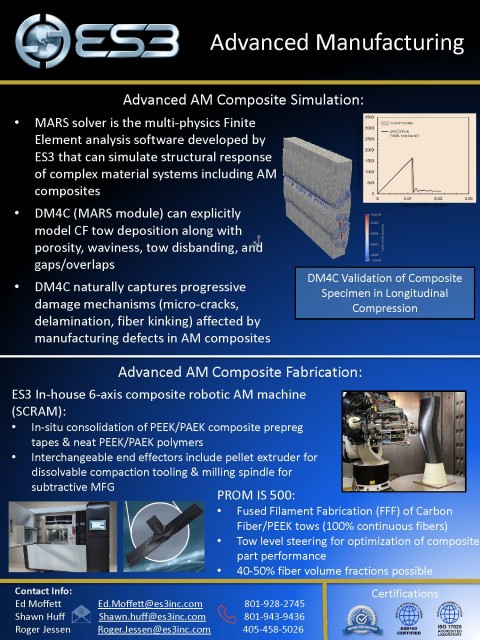

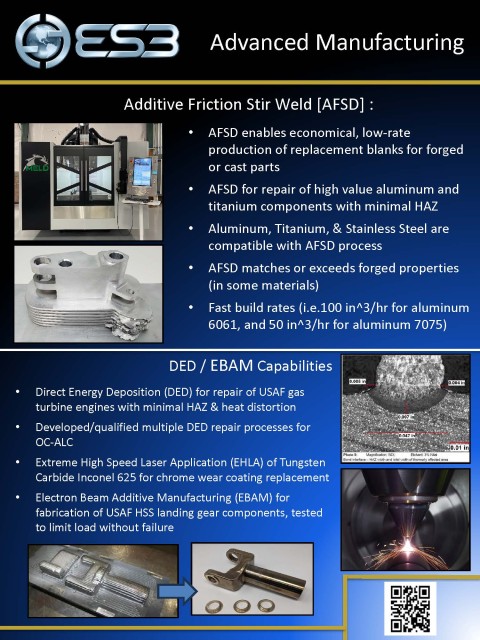

ES3 (es3inc.com) is a niche engineering firm providing specialized design, development, and fabrication of products for aerospace and other heavy industry sectors. ES3 designs, prototypes, tests, validates, and sells new component and new system product lines. Our advances in coatings qualify a range of high-performance finishes for industrial high-wear surfaces to aerospace safety-of-flight components to enhanced lightweight armors. Additive Manufacturing capabilities were developed for USAF challenges in castings and forgings needs, additionally Material Composite is part of our development having unique capability to predict AM composite material properties and their failure mechanisms.

4. ES3 Capabilities Brochure Short size (PDF file - 670KB)

Main exhibits 2

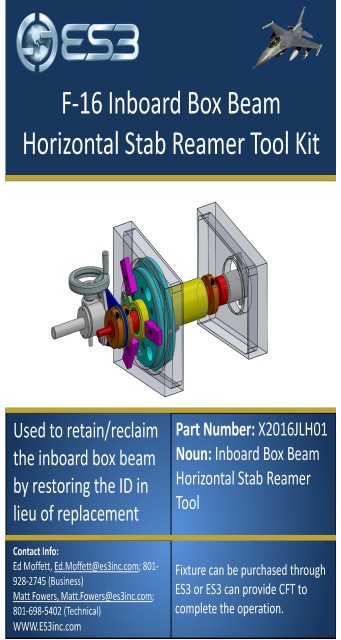

F-16 Integrity Structural MRO Services

ES3 provides extensive structural engineering, inspections, repairs, configuration changes, and spare parts supply for a wide range of F-16 fleets. Our support services are offered to the US and operated by the US and foreign militaries. Additionally, it is approved by the US Air Force F-16 System Program Office (SPO) at Hill Air Force Base as qualified to perform F-16 wing overhauls at our facility in Clearfield, Utah.

3. F-16 Wing overhaul program data sheet 9_7_23 (PDF file - 2,184KB)

Main exhibits 3

Additive Manufacturing & Aerospace Surface Finishing

ES3 is developing AM composite capabilities including Scalable Composite Robotic Additive Manufacturing (SCRAM) and AM single fiber tow deposition. Additionally, ES3 has the capability of replace the forgings and casting process through Electron Beam Additive Manufacturing (EBAM) developing technology. DM4C explicitly simulates composite tow deposition and matrix polymerization, enabling an ultra-high-fidelity description of bond formation and capture of mesoscale damage phenomena.