Exhibition category

Contact address

| Address | Kyobashi Toho Center Bldg. 3F, 2-5-2 Kyobashi, Chuo-ku, Tokyo 1040031, JAPAN |

|---|---|

| Telephone | 0335627787 |

| URL | https://www.maximator.de/flycms/en/web/454/-/homepage.html |

| salesteam@maximator.co.jp |

Main exhibits 1

Booster unit for Safety inspection/high pressure testing(KHK compliant )

以下は英訳です:

1. Maximum Discharge Pressure: 150 MPa

The maximum discharge pressure is 150 MPa, making it ideal for pressure resistance and airtightness testing of instruments and piping around accumulators for safety inspections, as well as for testing ultra-high-pressure equipment. The discharge rate is 93 NL/min at 125 MPa, allowing for rapid pressurization of workpieces. The medium used includes nitrogen and general gases.

2. Lightweight Design

The booster unit features an aluminum frame, achieving a lightweight design with a mass of approximately 65 kg. Comparable products typically have 2 to 3 times the mass (compared to our products), requiring heavy machinery for loading and unloading during transportation. However, the lightweight design allows for easy transportation using general vehicles.

3. Compliance with the High Pressure Gas Safety Act

The built-in booster in the main unit is an air-driven booster made by MAXIMATOR. Additionally, the high-pressure valves and fittings use steel types that comply with domestic regulations. While the external dimensions and mass are the same as conventional products, the tensile strength is higher, ensuring compliance with the High Pressure Gas Safety Act up to 150 MPa.

4. Ensuring Operator Safety

To ensure the safety of inspection workers on-site, an emergency stop button is provided, which stops the booster operation and is designed to quickly release any residual ultra-high-pressure gas within the system.

Main exhibits 2

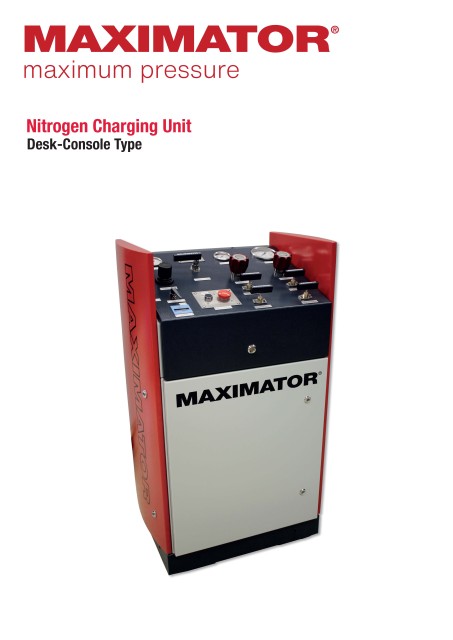

Nitrogen Charging

<Extensive lineup>

We offer Cylinder Trolley Type, Pushcart Type, Disc Type, and Unit Type to suit your usage environment.

The booster for each N2 charger can be changed to match the required discharge pressure.

After confirming your requirements, we will select a booster and assemble a system unit that suits your usage method and environment

to propose equipment that is easier for you to use.

Product Information Nitrogen Charging (PDF file - 4,071KB)

Main exhibits 3

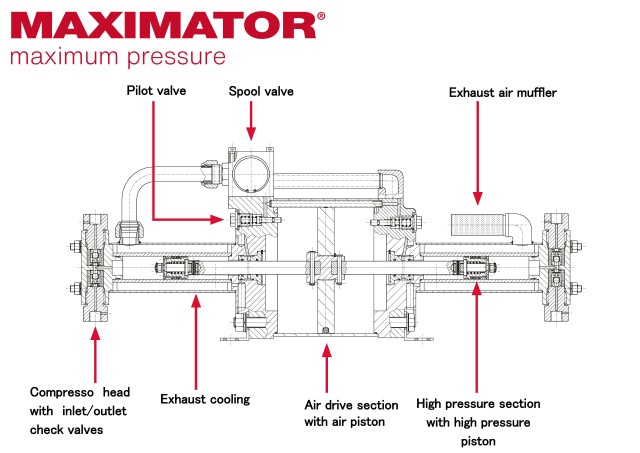

Air driven high pressure gas boosters

MAXIMATOR's gas boosters compress and increase the pressure of gas and air.

In addition to being compatible with industrial gases such as argon, helium, and nitrogen, they are also widely used for media (hydrogen, carbon dioxide, methane, and ammonia) toward a carbon-free society.

By installing auxiliary equipment before and after the gas booster, it is possible to control it and use it for various purposes.

<Features at a glance>

» Pressure regulation via manual pressure regulator or pneumatically actuated valve

» Operation with compressed air allows use in explosion-proof areas

» Gas booster automatically stops operating upon reaching pre-selected final pressure

» Gas booster restarts automatically to compensate leaks

» No power consumption during long pressure holding periods

» No heat generation during pressure holding period

» Easy installation and trouble-free handling of gas boosters

» Low maintenance thanks to reliable, easy-to-install devices

» Effective cooling of the high pressure cylinders through integrated exhaust air cooling

<Fields of applications>

»Gas compression with constant gas inlet pressure

»Gas compression with variable gas inlet pressure

»Gas compression for laboratory and production applications

»Gas compression for high pressure testing applications