Exhibition category

Contact address

| Address | 4-3-33, Omagari Industrial Park, Kitahiroshima City, Hokkaido, Japan 061-1274 |

|---|---|

| Telephone | 81113775766 |

| URL | https://world-yamauchi.co.jp |

| s_sofue@world-yamauchi.co.jp |

Main exhibits 1

Production Factory

Our company is capable of integrated production, from material shearing to painting, and we are committed to manufacturing and delivering even the smallest single part. We deliver our products to customers ranging from large enterprises to small and medium-sized businesses nationwide, and we are highly regarded for our work. A testament to this is the large number of repeat orders we receive.

In terms of production, we handle orders for products used in railway vehicles, industrial machinery, medical equipment, semiconductor components, and parts or components for seismic isolation devices. We carry out manufacturing, from design and development to detailed adjustments in line with the client's requirements. We were selected as a company eligible for subsidies under the Ministry of Economy, Trade, and Industry's domestic investment promotion project to strengthen supply chain measures. As a result, we have built a production plant for the manufacture of aircraft engine parts (including machining, laser welding, sheet metal processing, and unit assembly).

This new plant is equipped with various cutting-edge machines and features a centralized control room to manage operations through our in-house developed ERP system, with expert employees overseeing the management. Despite being located in Hokkaido, we receive a constant stream of repeat orders from customers across the country. We are a company that excels in quality, delivery time, cost, logistics, and customer service.

Main exhibits 2

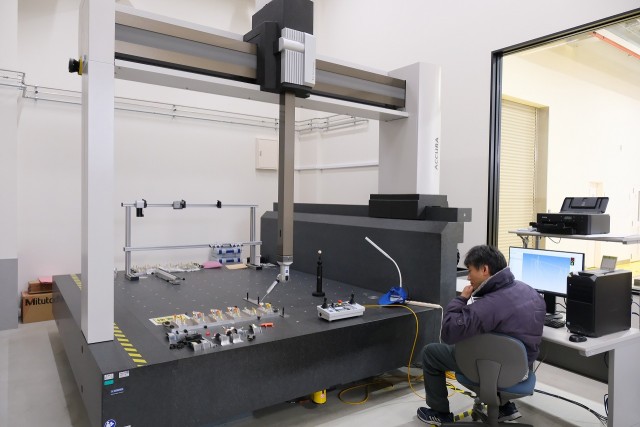

Latest Equipment

Our policy is to respond to orders for everything from small parts for home appliances to large units for construction, even if it’s just a single order. Experienced professionals, well-versed in systems, leverage their expertise to drive improvements in the internal flow of parts, manufacturing methods, process management, and more within the company. This includes the introduction of 5-axis machine tools, production robots, the visualization of work instructions, and the development and implementation of our own production management system, all propelled by their inherent vitality.

Leveraging these achievements and experiences, we have completed the construction of a new aircraft factory on our company premises, equipped with cutting-edge machinery. We have implemented our in-house developed production management system, enabling us to manage each factory, machinery, and work progress. By setting processing records as target values and continuously striving to exceed these targets daily, we work to reduce work time, setup time, and waiting time, all in an effort to cut costs.

To improve precision, we have increased our production capacity by revising machining methods to reduce the number of parts, streamlining the workflow to shorten overall process time, and adopting automated cutting machines and robots, along with their effective management.

Main exhibits 3

Samples

As specialists in metalworking, we design, develop, and use products like factory staircases, landings, and equipment ourselves, rather than relying on specialized companies. Our policy is to develop in-house whatever we can, and we have a track record in designing and manufacturing jigs for machining, inspection, and welding. We are also capable of proposing changes to the manufacturing processes of our clients based on their orders.

We believe in the integration of IoT and human capabilities. IoT implementation requires an understanding of the physical processes to effectively program it. Introducing the latest machines and systems shouldn’t increase the burden on workers—that would be counterproductive. A specialized team gathers feedback on the challenges and improvements desired by each worker to optimize the overall operation.

Such initiatives have led to our track record of designing and manufacturing factory parts, equipment parts, jig parts, and equipment systems in-house. Externally, we have a proven history in strategic foundational technology enhancement projects, such as the Supporting Industry Program, where we conducted research and development on low-distortion, high-strength technology using fiber laser welding robots for stainless steel.