Exhibition category

Contact address

| Address | Via Tacito 65, 41123 Modena, ITALY |

|---|---|

| Telephone | 0039059847337 |

| URL | http://www.dtm.it |

| info@dtm.it |

Main exhibits 1

Satellites, space vehicles and launchers structures

DTM is active since 1994 in the design, development and testing of aerospace structures, testing equipments and GSE (mechanical, fluidic, thermal ground support equipments) for satellites, launchers and experiments for manned or unmanned missions. Design tools include 3D CAD drafting and modelling software, structural, thermal and fluidic analysis as well as fracture control analysis software.

DTM facilities include grey areas for integration of small equipments, ISO6 clean room (ISO5 ready), tools and test equipments for manufacturing and testing of composite parts (autoclave), three thermal vacuum thermal chambers with temperature ranges from cryogenic up to 200°C and above, static and fatigue test jigs, shaker and many acquisition systems.

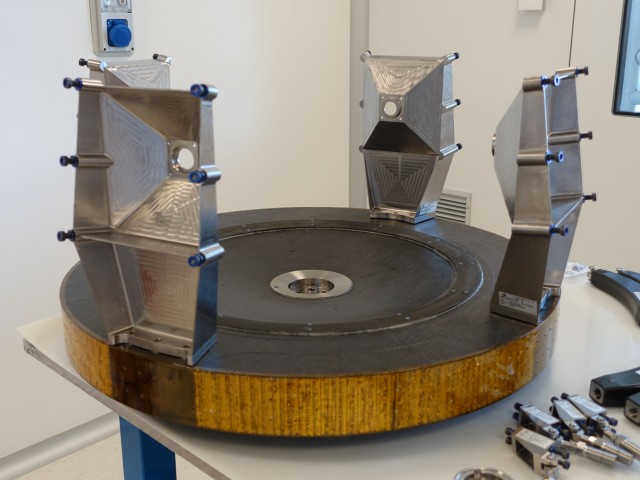

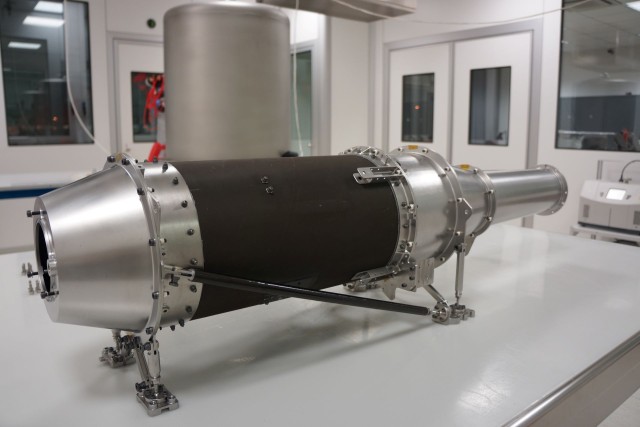

In the space field DTM main product services are related to design, manufacturing integration and testing of flight mechanical and fluidic systems like satellites primary, secondary and tertiary structures, cold plates for temperature control of flight hardware, as well as mechanical parts belonging to payloads, instruments or antennas.

DTM quality management system is certified according to ISO 9001:2015 and EN-9100:2018. Main customers in the space field are ESA, ASI, Airbus, Thales Alenia Space and Leonardo. DTM is also involved in activities in industrial fields like marine, automotive and biomedical sectors.

DTM Brochure 2023 (PDF file - 7,424KB)

Main exhibits 2

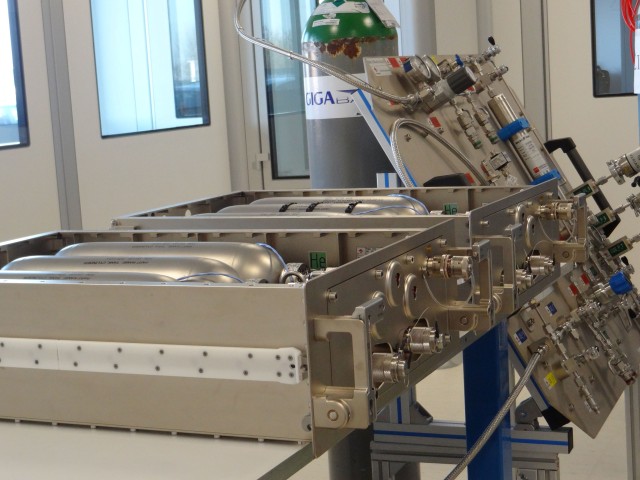

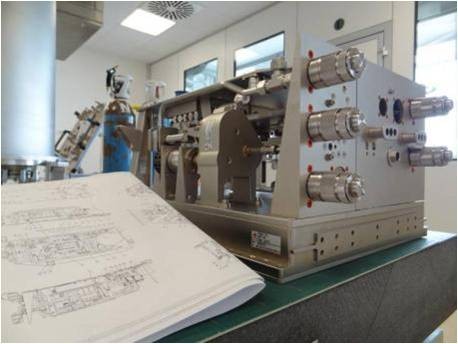

Cold plates and fluidic equipments. Facilities for ISS and gateways

In the space field DTM main product services are related to design, manufacturing integration and testing of flight mechanical and fluidic systems like cold plates for temperature control of flight hardware (MPCV service module for Orion space vehicle and I-HAB)

DTM since many years is developing facilities for manned and unmanned missions: International Space Station, sounding rockets and parabolic flights. Among the various developments DTM designed and developed many extra high purity gas delivery systems for ISS as well as thermal control systems and scientific experiments for microgravity manned missions.

DTM is developing since many years fluidic parts (including custom ones like valves, filling equipments) for special applications with demanding cleanliness, molecular and contamination requirements including extra high pure gas delivery systems (Exomars).

DTM Brochure 2023 (PDF file - 7,424KB)

Main exhibits 3

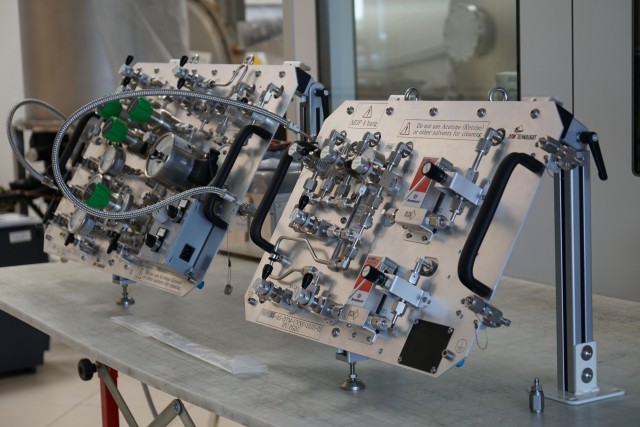

Mechanical, fluidic and thermal ground support equipments. Testing equipments

For ground support equipments DTM main products are related to design, manufacturing integration and testing of mechanical, fluidic and thermal GSE for integration, transportation and testing of flight components. DTM has designed and developed the mechanical GSE for the Sentinel 5 Instrument (Airbus prime) as well as several fluidic ground support equipments and custom thermal vacuum chambers for Thales Alenia Space.

DTM has also developed several custom test equipments for qualification and acceptance of space structures like Vega interstage 2-3, satellite structures and space vehicle structural parts.

DTM is a qualified laboratory of Emilia Romagna High Technology network and is member of ANSER Emilia Romagna aerospace consortium (AeroNautics and Space in Emilia-Romagna).