Aerospace in Japan today

Dependable technologies

<Defense craft>

Featured below are models currently in development, or already being deployed by the Japanese Ministry of Defense.

US-2 large rescue craft

The successor to the US-1A model. Development began in 1996, the first successful test flight was in December 2003, and deployment commenced in March 2007.

US-2 large rescue craft (ShinMaywa Industries)

P-1 fixed-wing patrol aircraft, XC-2 next-generation transport aircraft

The P-1 and XC-2 were based on the P-3C and C-1, respectively. Development of both aircraft began simultaneously in 2001, with some design elements shared to help reduce costs.

The P-1 had its first successful test flight in September 2007, and first saw distribution in 2008. The XC-2 prototype was launched in January 2010, and is scheduled for deployment in 2011.

P-1 fixed wing patrol aircraft (Kawasaki Heavy Industries)

XC-2 next-generation transport aircraft (Kawasaki Heavy Industries)

Unmanned aircraft

Development is underway of an unmanned version of the F-104 fighter jet. The systems being researched will allow autonomous flight and landings.

Unmanned craft development system (Fuji Heavy Industries)

T-4 intermediate jet trainer aircraft, T-7 primary jet trainer aircraft

Trainers like the T-4 and T-7 are the products of distinctively Japanese design and manufacture processes. The T-4 is particularly notable for a wholly domestic fuselage and engine. These agile aircraft are also used by the “Blue Impulse”aerobatic demonstration team, which astounds crowds at air base flight demonstrations around the country.

T-4 intermediate jet trainer aircraft (Kawasaki Heavy Industries)

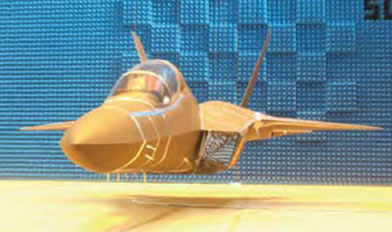

Prototype high mobility stealth aircraft

Japanese industries are conducting tests for a new aircraft which combines a stealthy shape, made from new synthetic materials, with highly mobile flight control. This cutting-edge design will gauge stealth capabilities under real flight conditions, and test the technologies necessary for future military aircraft.

This project contributes not only to the design and manufacture of civilian aircraft, but to a broad range of other industries, and the basic foundations of Japanese industry as a whole.

Prototype high mobility stealth aircraft (full-sized RCS test model)

<Aircraft developed through international collaborations>

Japanese industries currently play a major role in global production. A list of these overseas collaborative projects can be found below.

In the late 1970s, Japanese industries joined the Boeing B767 project during the detailed design phase, and worked primarily on the fuselage structure. Participation in international development projects later grew, and in the 2000s, Japan joined the B787 project during the theoretical design phase, taking charge of the main wing design and other challenging areas. Since then, the nation’s expertise has expanded from design and manufacture into testing and TC acquisition.

| Project | Responsible areas | Type of participation* |

|---|---|---|

| Boeing B767 | Front and rear fuselage, main wing, etc. | Program partner, 15% |

| Boeing B777 | Central, front and rear fuselage, etc. | Program partner, 21% |

| Boeing B787 | Main and central wing, front fuselage, etc. | Program partner, 35% |

| Bombardier Aerospace Global Express | Main wing, central fuselage | RSP |

| Bombardier Aerospace CRJ700/900 | Tail fuselage, nose and main landing gear | |

| Embraer 170/190 | Main and central wing | |

| Raytheon Aircraft Hawker 4000 | Main wing structural system | |

| Gulfstream Aerospace Gulfstream | Flaps, landing gear actuators, etc. | Supplier |

| Airbus A380 | Freight doors, vertical tail fin parts, titanium sheets, carbon fibers, cisterns, etc. | Supplier |

* Program partner: A specific area is handled from development all the way to production. Risks for those phases, as well as sales and trade, are born based on the original contract.

* RSP (Revenue Sharing Partner): Development and mass production are separated. Revenue is earned according to the amount of participation.

* Supplier: Development and production are carried out in accordance with plans decided by the producer of the final product, and other partners.

Boeing B787 test flight

Airbus A380

<Helicopters>

The world’s fifth largest user of helicopters, Japan domestically develops and produces everything from fuselages to engines. In fact, the fuselages, as well as Japanese-manufactured transmissions, have earned global acclaim.

A helicopter’s most crucial technological component is its rotor system, for which Japan has produced a bearing-less system utilizing the latest technologies from around the world. Japan has also taken the initiative in joining international joint development projects.

BK117C-2 (Kawasaki Heavy Industries)

OH-1 (Kawasaki Heavy Industries)

Engines Equipment

<Aircraft engines>

Japan has a range of development projects underway for both military and civilian aircraft engines, utilizing the latest technologies and its own unique designs. Projects are particularly active in the civilian field, where Japan plays key roles for the CF34, TRENT1000 and GEnx engines

| Engine | Aircraft | Parts produced | Participation* |

|---|---|---|---|

| Rolls-Royce TRENT1000 | Boeing B787 | Intermediate-pressure compressor modules, burner modules, low-pressure turbines | RSP, 16% |

| General Electric GEnx | Boeing B787 | Low-pressure turbines, high-pressure compressors, shafts and burner casings | RSP 15%, subcontractor |

| Rolls-Royce TRENT900 | Airbus A380 | Low-pressure turbine blades, Intermediate-pressure compressor casings | Subcontractor |

| Rolls-Royce TRENT500 | Airbus A340 | Intermediate- and low-pressure turbine blades, compressor casings, turbine casings, etc. | RSP, 20% |

| General Electric CF34-8/10 | Bombardier Aerospace CRJ700/900, EEMBRAER 170/190, Commercial Aircraft Corporation of China ARJ21 | Low-pressure turbine modules, high-pressure compressor aft part, rotor fan, gearbox, etc. | RSP, 30% |

| Pratt and Whitney PW4000 | Airbus A310/330/340 | Low-pressure turbine blades, discs, burners, active clearance control, etc. | RSP 11%, subcontractor |

| General Electric GE90 | Boeing B777 | Low-pressure turbine rotor blades, discs, long shafts, etc. | RSP, 10% |

| Rolls-Royce TRENT700/800 | Airbus A330, Boeing B777 | Low-pressure turbine blades, discs, long shafts, low-pressure turbine discs, turbine casings | RSP, 8-9% |

| International Aero Engines V2500 | Airbus A320, McDonnell Douglas MD90 | Fans, low-pressure compressors, fan casings, etc. | Program partner, 23% |

* RSP (Revenue Sharing Partner) : Development and mass production are separated. Revenue is earned according to the amount of participation.

* Subcontractor : Produces according to a supply schematic provided by a partner or the maker of the final product.

* Program partner : A specific area is handled from development all the way to production. Risks for those phases, as well as sales and trade, are born based on the original contract.

Rolls-Royce TRENT 1000

General Electric GEnx

<Equipment>

Aircraft require a vast array of equipment, each piece of which must be as dependable as the body of the plane itself. Japan’s manufacturing industries work to provide a stable supply of these parts to its defense forces, creating the bases of production and repair.

Opportunities are also growing in the global civilian market. Several Japanese manufacturers joined in the international development of the Boeing B777 wide-body twin-engine aircraft.

Flight control hydraulics (Nabtesco)

Flap drive systems (Shimadzu)

Air conditioning systems (Sumitomo Seimitsu/Hamilton)

Aerospace gauges (Yokogawa Electric)

Landing gear (Sumitomo Seimitsu)

Airplane toilets (JAMCO)

<Cutting-edge materials>

Composite materials, particularly carbon fiber reinforced plastics (CFRP), are being used increasingly for aircraft construction. Japan holds a 70% global share for these carbon fibers, and uses the latest composite manufacture techniques to produce the main wing, central wing and other key parts of the Boeing B787 mid-size jet, a next-generation aircraft that is 50% composites. The next promising aerospace material is titanium alloy, which Japanese precision forging and casting techniques turn into fan casings and turbine blades for jet engines.

The upcoming Mitsubishi Regional Jet (MRJ), a domestically produced regional passenger jet, will bring all of these new materials together.

Carbon fibers (Toray)

Raw carbon (Toray)

V2500 fan casings (Kobelco)

The space industry

<Rockets>

Japan’s space industry seeks to independently explore and utilize outer space. To this end, it has developed and deployed the H-IIA, a liquid fuel rocket which ranks among the world’s foremost models, as well as the M-V model line, which boasts the largest scale of any solid fuel rocket system in the world. Launch systems, satellite tracking and control systems help secure and maintain these domestic space projects.

The launch of the H-IIB2(JAXA)

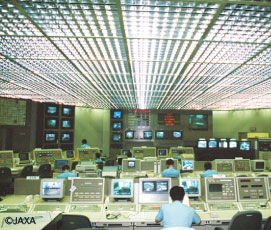

The launch control room at Tanegashima Space Center(JAXA)

| No | H-IIA | H-IIB | M-V | |

|---|---|---|---|---|

| 1 | Total length | 53m | 57m | 30.8m |

| 2 | Radius | 4.0m | 5.2m | 2.5m |

| 3 | Maximum load (w/o payload) | 289t | 531t | 137.5t |

| 4 | Low earth orbit launch capability | ~10t | ~16.5t | 1.85t |

| 5 | Geostationary transfer orbit launch capability | ~4.0t | ~9t | - |

<Satellites>

Japan’s projects in this field serve as real-world tests of its observational satellite technology.

In 1995, a Japanese astronaut boarded a space shuttle to retrieve a Space Flyer Unit which had carried out a variety of observations and experiments in space.

Launched in September 2007, the lunar orbiter “Kaguya” became the only vessel since the Apollo Project to truly explore the moon’s surface. It completed as many as fifteen observation missions over its two years of operation.

Yet another of Japan’s outstanding achievements is the asteroid probe “Hayabusa.”Sent into space via the M-V5 rocket in May 2003, it touched down on the Itokawa asteroid to gather samples that it delivered to Earth in June 2010.

Samples retrieved by the asteroid exploring satellite “Hayabusa”(JAXA)

An on-board capsule from “Hayabusa", retrieved on land (JAXA)